Seeking 250 new employees in Cherbourg, France: Help produce the largest offshore wind turbine blades ever manufactured!

Today, June 18, we’re thrilled to announce our plan to recruit 250 employees at our wind turbine blade manufacturing site in cherbourg, france, by the first quarter of 2021. Every new hire will go through an intensive training program at the factory's ‘center of excellence' to learn wind turbine blade manufacturing processes. The expanded production workforce will allow our company to answer to industry demand

Opened two years ago in April 2018, the Cherbourg factory today counts more than 300 employees, 34 percent being women. The facility became the first wind turbine blade manufacturing site in France.

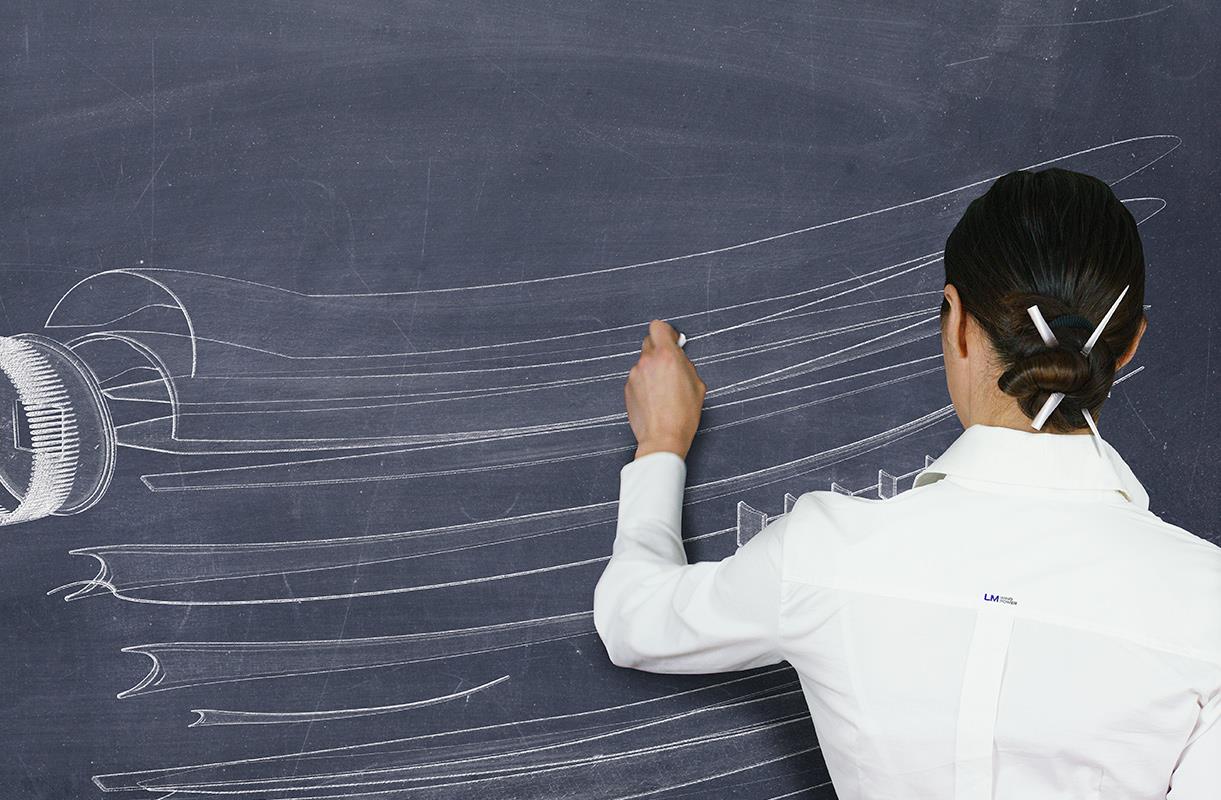

The facility has produced the world’s largest offshore wind turbine blade ever manufactured, 107-meters long, dedicated to GE’s Haliade-X 12MW offshore wind turbine. In 2019, two blades were shipped to testing facilities, and three were assembled on the Haliade-X validation unit in Rotterdam, the Netherlands. The Cherbourg site has now started commercial production.

Henrik Ravn, the Site Director, said: "Cherbourg is the world’s first and only factory to produce a blade longer than 100-meters. It’s a great milestone for the wind industry, but also an outstanding achievement for the teams. This could not have happened without their passion and commitment. We are proud to take part in the region’s social and economic development, to create more jobs in the surrounding community, but also to bring new skills to Normandy’s workforce."

The Cherbourg team is mostly looking to expand its production workforce, with positions that are open to all profiles and backgrounds. Every new employee will be trained to manufacture wind turbine blades through our ‘Center of Excellence' training program – a six-week theoretical and practical training course, which will develop the skills and technical expertise required to produce high-quality wind turbine blades. The site will also be looking for production supervisors, quality controllers, logistic and maintenance technicians, as well as apprentices' positions.

Following the training, employees receive official certificates recognized in the French industry, as a Qualification Certificates for Metallurgy in Operations.

Read the full announcement from GE Renewable Energy.

Visit our jobs page to learn more about applying to work in Cherbourg.

CAREER

Join our team

Learn more about the Cherbourg wind turbine blade factory, and apply to join the team.