What is a wind class?

When it comes to wind turbine performance, location matters. Turbines need to be designed for optimal performance and reliability in whatever weather conditions they may face throughout their lifetimes, be it a gentle breeze on a low-lying plain or a raging offshore storm.

Before deciding to build a wind turbine in a particular site, there are a few critical questions the developer needs to answer: What is the average annual wind speed in this location? What are the extreme gusts that could occur within a 50 year period? How turbulent is the wind at the site?

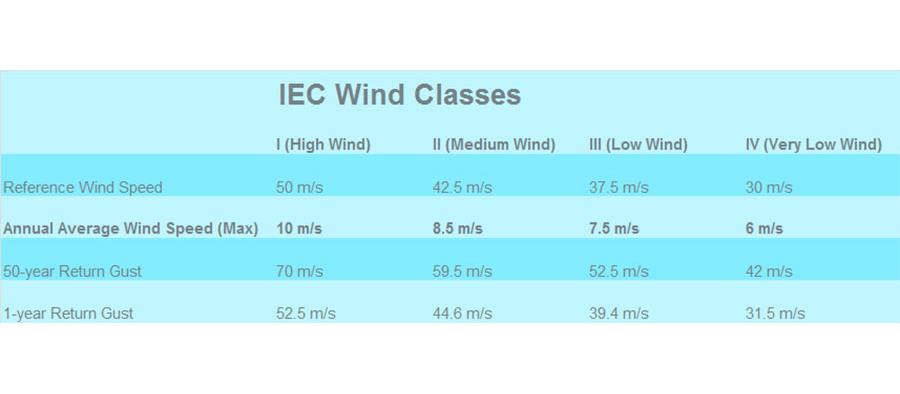

These three dimensions — wind speed, extreme gusts, and turbulence — encompass the wind class of a wind turbine. The International Electrotechnical Commission (IEC) sets international standards for the wind speeds each wind class must withstand, as seen in the table below.

How does this impact blade design?

To put it simply, blades in high wind sites and low wind sites have different designs to optimize performance. For instance, turbines in lower wind speed locations (Wind Class III) at a given rated power will need a larger rotor to capture the same amount of energy as a similar turbine at a Class II site. Fortunately the milder wind climate makes it possible for the turbine structure to carry a larger rotor, and thus an efficient turbine can be designed. Even so, the cost of energy will always be lower for wind power at sites with a higher average wind speed.

The choice of wind class occurs early in a blade project, with the customer making the decision about the wind class based on the intended site. According to LM Wind Power’s Peter Hansen, Senior Project Manager for Technical Business Development, Wind Class II and III are most common, though this is changing over time.

“The main difference between wind classes is in the loads, which the customers calculate and give to us,” Peter said. “There is a clear trend in the market toward more Wind Class III turbines in low wind sites, and the explanation is simple: there are not many Wind Class I and II sites left!”

What are the wind classes of our blades?

Customers’ desires, and consequently our blade designs, are not static over time. When we design a blade for a customer, sometimes they want to use it on turbines in a different environment than the original site, which may be more windy or turbulent.

“We may design blades for the same customer in the same length, but with different wind classes and different masses,” Peter said. For example, the LM 58.7P is in Wind Class III, while the LM 58.7P2 is in Wind Class II. Though both blades are 58.7 meters in length, the blade mass differs: 13320 kg for the LM 58.7P and 13770 kg for the LM 58.7P2.

References:

What is the wind class of a wind turbine?

IEC Wind Turbine Classes